| Place of Origin: | Hebei,China(mainland) |

| Brand Name: | LVJOE |

| Certification: | ISO CE |

| Model Number: | FM1300 |

| Minimum Order Quantity: | 1 line |

|---|---|

| Price: | Negotiation |

| Packaging Details: | standard package |

| Delivery Time: | 2 Months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 lines per year |

| Features: | High Automatic | Condition: | New |

|---|---|---|---|

| Dimension(L*W*H): | 12600*1950*1600mm | Power: | 30KW To 100KW |

| Experience: | 15 Years | Voltage: | 380V, 50HZ |

| After-sales Service: | Engineers Available To Service Overseas | Max Speed Size: | 1300mm |

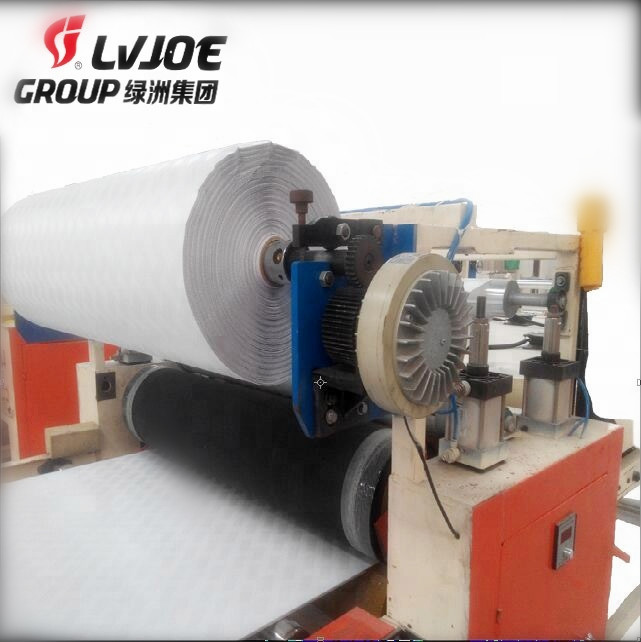

Automatic Gypsum Board Lamination Machine / Gypsum Ceiling Pressing Machine

PVC gypsum ceiling tile is made of paper-faced board with a layer of PVC on surface and aliminum foil on its back. it is a enviromental friendly, light weight, fireproof, waterproof and corrosion-resistant decorative ceiling board. it is easy to clean,and the patterns can be customized, it can be widely used in high fireproof and waterproof requirement enviroment, such as hotels, restaurants, shooping malls, theaters, stations,auditoriums, offices,living rooms, office buildings, electroic computer rooms, preision instrument rooms, and interior decoration of factories or houses.

PVC Gypsum Ceiling Tile Size:

|

Size(mm) |

595*595*8.0 |

| 603*603*8.0 | |

| 600*1200*8.0 |

Double sided laminating machine flowchart:

Automatic feeding→ dust cleaning →PVC film and aluminum foil laminating→ film cutting(manual/automatic)→conveying →vertical cutting(dust collecting)→horizontal cutting(dust collecting)→small board stacking →edge sealing →stretch packing →finished products stacking

Technical parameter:

|

Effective laminating width

|

1300mm

|

|

Sheet thickness

|

5-30mm

|

|

Laminating speed

|

15m/min

|

|

Speed adjustment way

|

Frequency conversion synchronous speed regulating

|

|

Electrical control

|

PLC

|

|

Annual capacity

|

2-4 million Sq.m

|

|

Film material

|

PVC film, aluminum foils, decorative material, etc.

|

|

Board sheet material

|

PVC baseboard, gypsum board, wood board,sectional board, PVC foam board,etcProduct Overviews 11

|

Single side lamination machine production process:

Automatic board feeding——pre dusting——coating——drying and conveying—— aluminum foil unwinding——pneumatic lamination for film and gypsum board——cutting——conveying——automatic overturn——coating——drying and conveying——PVC film unwinding——pneumatic lamination for film and gypsum board——cutting(manual,automatic)——drying and conveying——lengthwise cutting——horizontal cutting——belt conveyor output——autolift stacking conveying——stretch packing——conveying——lift(finished products stacking)

Advantage:

Easy to install and easy to operate

Full-automatic and semi-automatic

Saving energy and labor cost

High efficiency,high output

Fast delivery ,good after-sales service

Contact way:

Wechat/ WhatsApp:17732172215

Skype: 16630111157

Email:17732172215@sina.cn

Contact Person: ZiZi Li

Tel: +8617732172215

Low Price Automatic Saw Machine For Gypsum Board Eco Friendly

Low Cost Plaster Board PVC and PET Full Automatic Laminating Line

Double Sides Full Automatic PVC Laminated Gypsum Ceiling Board Production Line

PLC System Gypsum Board Ceiling Making Punch Machine Saving Energy

Full Automatic Sheet Perforation Machine Gypsum Board Hydraulic Hole Punching Machine

Decorative Drywall Sheet Perforation Machine For Square / Round Hole

Heat Insulation Mineral Fiber Ceiling Board Machine Energy Saving

Automatic Operation Mineral Fiber Ceiling Board Machine With Waterproof / Fireproof

Light Weight Mineral Wool Board Production Line For Construction Material