| Place of Origin: | Hebei, China (Mainland) |

| Brand Name: | Lvjoe |

| Certification: | CE ISO |

| Model Number: | LV-BM01 |

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Standard exportation package or customized mgo board making machine |

| Delivery Time: | Shipped in 60 days after payment |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year mgo board making machine |

| Voltage: | 380v Or Customized | Warranty: | One Year |

|---|---|---|---|

| Production Line Control: | PLC Control System | Condition: | New |

| Main Process: | Main Process: Batching, Forming, Cutting | Power(W): | As Per Actual Requirement |

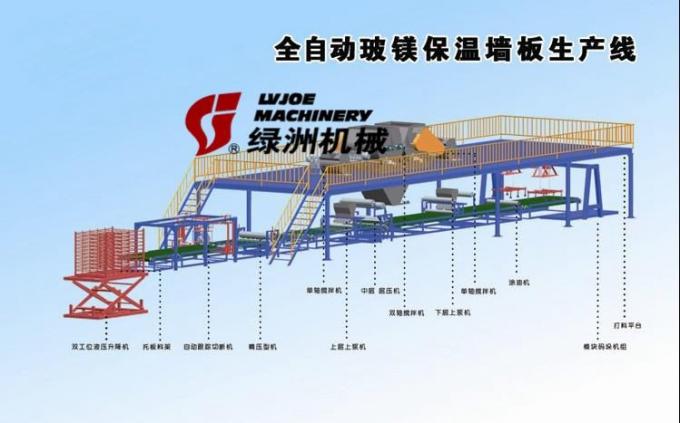

Fire Resistant Interior Composite Partition MGO Board Production Line

Product Description:

1. Production Line

Mgo board making machine can produce all kinds of magnesium oxide boards, they can be used for ceiling, wall skirting,

decorating of indoor wall and lining board for furniture. It can replace three-ply board, five-ply board, flake board, MDF

(Medium Density Fiberboard ) and Gypsum Board. It is really environment product and lower cost.

2. Raw material and cost analysis

The product is formed with crushed crop straw or sawdust and some inorganic chemical materials at one time after

roller-extruding. The source of raw materials is widely and they are purchased easily for customers.

3. Technology features

There is not any requirement about high temperature and high pressure during production processing. The board will

be formed at one time after roller-extruding under the conditions of normal temperature and normal pressure. This is

a green environmental-protection project, because that there is no waste water, waste materials and waste gas during

its production processing. The finished board doesn't need high temperature drying, air-drying and watering, and under

the normal temperature, they will dry well indoor.

4. Equipment Model and Product Specification

According to different production, our equipment has 6 models for large-scale, middle-scale and small-scale. Our all

equipment can produce board with same quality and specification but different production.

The board with the thickness of 2-60mm, the biggest width of 1, 300mm and unlimited length. So you can adjust the

thickness of board at will. The standard specification of the board is 1.22mX2.44m.

Mgo board specifications:

| thickness | 3-20mm |

| length*width |

2440*1220mm 2400*900mm 3000*1200mm 2750*1200mm |

MgO Board performance:

A. Oxygenic index%: >90

B. Level combustion: SO

C. Vertical combustion: SO

D. Water content rate: 10.9%

E. Capacity: 1.15g/cm3

F. Static bending intensity: 169.46Mpa

G. Density: T/ m3 1.13

H. Water resistance: Without chalking for 24 hours and there is no change on surface

I. No “Three-wastes” (waste water, waste gas and waste residue), no pollution and environmental protection

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Company Information

The company was divided into R&D center of plasterboard equipment ,manufacturing

base and machinery Import & Export company. Our products are exported to Asia,Europe,and Middle East etc.

LVJOE has 300 employees, including 6 professor senior engineers, over 40 of senior technical staff,Our core

product:plasterboard production line(also known asdrywall production line, paper faced gypsum board production line),

gypsum ceiling board equipment and laminating machine of various materials.

Name: Automatic tracking cutting machine for mgo board prodction line.

Brand: LVJOE

Original: China

Automatic tracking cutting machine adopts fixed length cutting method,cutter does not hurt the template.

Contact Person: James Yang

Tel: +8615832254694

Low Price Automatic Saw Machine For Gypsum Board Eco Friendly

Low Cost Plaster Board PVC and PET Full Automatic Laminating Line

Double Sides Full Automatic PVC Laminated Gypsum Ceiling Board Production Line

PLC System Gypsum Board Ceiling Making Punch Machine Saving Energy

Full Automatic Sheet Perforation Machine Gypsum Board Hydraulic Hole Punching Machine

Decorative Drywall Sheet Perforation Machine For Square / Round Hole

Heat Insulation Mineral Fiber Ceiling Board Machine Energy Saving

Automatic Operation Mineral Fiber Ceiling Board Machine With Waterproof / Fireproof

Light Weight Mineral Wool Board Production Line For Construction Material