| Place of Origin: | Hebei, China (Mainland) |

| Brand Name: | LVJOE |

| Certification: | CE ISO9001 |

| Model Number: | LV-BM02 |

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Standard exportation package or customized mgo board making machine |

| Delivery Time: | Shipped in 60 days after payment |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year mgo board making machine |

| Power(W): | As Per Actual Requirement | Condition: | New |

|---|---|---|---|

| Production Line Control: | PLC Control System | Voltage: | 380v Or Customized |

| Warranty: | 1 Year | Main Process: | Batching, Forming, Cutting |

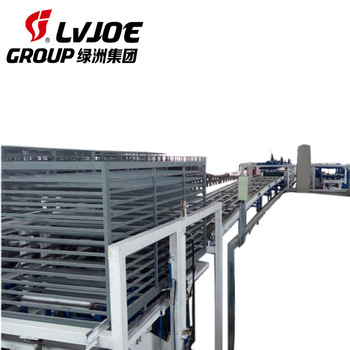

Exterior Decorative Fireproof Board MGO Wall Panel MGO Board Production Line

Product Description

1. Specification of production line of making incombutible mgo boards materials

1. Capacity: 500-3000 pcs per day

2. Automation: simple line,semi degree automatic or high degree automatic

3. Main materials: magnesium oxide, magnesium chloride, perlite, non-woven fabrics, glass, colth, sawdust, water

4. Dimension of product:

Thickness: 3mm-25mm

width: 1200mm or 1220mm

length: 2400mm~3600mm

we can design and manufacture products of other dimensions as clients’ special requirement.

5. Advantage:

(1) the equipment structure is reasonable, energy saving ,high degree of automation , producing cost is low , have

competitive advantage .

(2) We can offer the services of design, producing, installation, commissioning and training, as well as turnkey project

for customers.

| Specification for the automatic tracking cutting machine | |

| Cutting speed | 6pcs/min |

| Cutting motor power | 1.5kw -2.2kw |

| The disc cutter blade | 280mm |

2. Equipment characteristics

Multifunctional thermal insulation board production line is designed with continuous roller press board making technology.

The whole production process is accomplished with the following steps: thermal insulation layer settling, mesh spreading,

material feeding, compounding, repressing, following and wet cutting, secondary dividing and cutting, and automatic board

stitching. The equipment runs stablely with simple operation and has a high automation degree.

3. Project Features

1. Wide source of production raw materials with no regional restriction. The product is formed at one-time through the

processing of cement, river sand, various thermal insulation materials, chopped fiber or glass fabric, etc. The production

technology is simple, low cost, needs small investment and has fast effectiveness.

2. Low energy consumption in production process. No requirement for high temperature or high pressure. One-time forming

at normal temperature, no special requirement for production site and so on.

4. Raw material and cost analysis

The product is formed with crushed crop straw or sawdust and some inorganic chemical materials at one time after roller-extruding.

The source of raw materials is widely and they are purchased easily for customers.

5. Application of MGO

The partition wall system, ceiling system, pipeline, decoration, building interlayer, sound insulation system, heat insulation

system, fire prevention partition area and wall guard board with high requirements of fire protection, environmental protection

and durability are especially suitable for five-star hotels, high-level clubs, cinemas, Airport Railway stations, hospitals, schools,

nightclubs, KTV, gymnasiums and high-level office buildings.

6.Our Services

1. Best Price; we have our own factory, who has been specialized in full automatic pvc laminated gypsum

ceiling tiles machine for more than 15 years, and you are welcome to our factory any time.

2. Superior Quality; quality is the life of all our business.

3. Best Service; we are the special International Trading Company of our factory, and especially focus on

exporting business.

4. Best after-sale service; our engineers will design scale of whole production line and help you with

installation and commissioning, and train your workers or employees until they know how to operate all equipment.

7.Company Information

HEBEI LVJOE MACHINERY MANUFACTURING CO.,LTD. established in 1998, is a large manufacturer

of integrated supply dedicated in researching,manufacturing,trading of plasterboard machinery. We are

HEBEI province municipal civilized and creditable unit,with high-tech enterprise certificate issued by the

state,national patent licenses,CE qualitysystem certification issued by the EU,and ISO9001 quality

system certification.

James Yang

ADD: 17th, NanYan Road Economical and Technological

Development Zone,Shijiazhuang City,Hebei,China

Mobile Phone:+8615832254694

WeChat:15832254694

E-mail:lvjoe3@greensontech.com

Contact Person: James Yang

Tel: +8615832254694

Low Price Automatic Saw Machine For Gypsum Board Eco Friendly

Low Cost Plaster Board PVC and PET Full Automatic Laminating Line

Double Sides Full Automatic PVC Laminated Gypsum Ceiling Board Production Line

PLC System Gypsum Board Ceiling Making Punch Machine Saving Energy

Full Automatic Sheet Perforation Machine Gypsum Board Hydraulic Hole Punching Machine

Decorative Drywall Sheet Perforation Machine For Square / Round Hole

Heat Insulation Mineral Fiber Ceiling Board Machine Energy Saving

Automatic Operation Mineral Fiber Ceiling Board Machine With Waterproof / Fireproof

Light Weight Mineral Wool Board Production Line For Construction Material