| Place of Origin: | Hebei,China(mainland) |

| Brand Name: | LVJOE |

| Certification: | CE ISO |

| Model Number: | LV-BM |

| Minimum Order Quantity: | 1 Line |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Standard package |

| Delivery Time: | 2 Months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 lines per year |

| Control System: | PLC | Materials: | Stainless Steel, Alloy, Super Carbon-steel |

|---|---|---|---|

| Application: | Producing Gypsum Cornice | Mold Material: | Aluminium Alloy |

| Advantages: | High Output, Economic | Electrical Parts: | Siemens Or Famous Domestic Brand |

| Warranty: | 1 Year | After-sales Service Provided: | Engineers Available To Service Oversaeas |

Full Automatic And High Capacity Magnesium Oxide Plate Making Machine

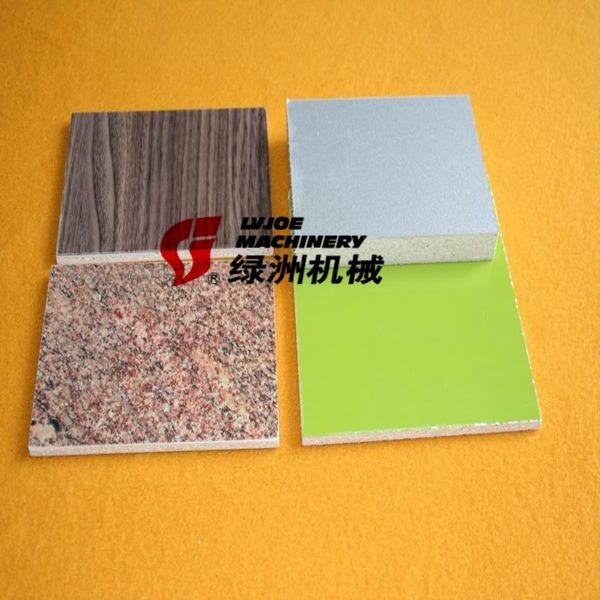

Magnesium oxide board is the building material widely used in the construction area.The stable magnesium colloid is reinforced by middle alkali glass fiber net and stuffed by light material then becomes new flameless decorative material.

Composition:The materials of paper magnesium fireproof board are Magnesia(Mgo), Magnesium Chlorid(MgCl2) and alkali glass fiber net.

Applications: Internal and external walls, hotels, restaurants, factory shopping malls, cinemas, theatres, hospitals, train or bus terminals, airports, and school constructions.

Specifications:

2,440*1,220mm,2400*900m600*600mm

Thickness: 3 - 20mm

Different sizes are available.

3000*1200mm,2750*1200mm,1,830*915mm

Equipment characteristics:

Multifunctional thermal insulation board production line is designed with continuous roller press board making technology.

The whole production process is accomplished with the following steps: thermal insulation layer settling, mesh spreading, material feeding, compounding, repressing, following and wet cutting, secondary dividing and cutting, and automatic board stitching. The equipment runs steadily with simple operation and has a high automation degree.

We can produce all kinds of thermal insulating and energy saving products of different specifications and materials (The main thermal insulation body of thermal insulation board materials can be foaming polystyrene board, extruded polystyrene board, rock wool board, glass wool board, VIVA, wood-wool cement board, FOREX fiber cement board and other materials.)

The smooth surfaced, flat and dense product has completely changed the cumbersome operation technology of expand polystyrene board thin plastering wall thermal insulation project, providing a faster operation speed and more economic benefit.

Project Features:

1. Wide source of production raw materials with no regional restriction. The product is formed at one-time through the processing of cement, river sand, various thermal insulation materials, chopped fiber or glass fabric, etc. The production technology is simple, low cost, needs small investment and has fast effectiveness.

2. The equipment is with high automation degree, simple production (operator can work after simple training), low labor intensity and assembly line operation. There is no noise, pollution or three-waste emission during production.

3. Low energy consumption in production process. No requirement for high temperature or high pressure. One-time forming at normal temperature, no special requirement for production site and so on.

4. According to the different requirements of different customers, we can produce various thermal insulation boards of different specifications (length, width, height) and different materials so as to meet the needs of different consumers.

Contact way:

Email:17732172215@sina.cn

Wechat and Telephone:17732172215

Contact Person: ZiZi Li

Tel: +8617732172215

Low Price Automatic Saw Machine For Gypsum Board Eco Friendly

Low Cost Plaster Board PVC and PET Full Automatic Laminating Line

Double Sides Full Automatic PVC Laminated Gypsum Ceiling Board Production Line

PLC System Gypsum Board Ceiling Making Punch Machine Saving Energy

Full Automatic Sheet Perforation Machine Gypsum Board Hydraulic Hole Punching Machine

Decorative Drywall Sheet Perforation Machine For Square / Round Hole

Heat Insulation Mineral Fiber Ceiling Board Machine Energy Saving

Automatic Operation Mineral Fiber Ceiling Board Machine With Waterproof / Fireproof

Light Weight Mineral Wool Board Production Line For Construction Material