| Place of Origin: | Hebei China |

| Brand Name: | GREENS |

| Certification: | ISO |

| Model Number: | GS |

| Minimum Order Quantity: | 1 Line |

|---|---|

| Price: | Negotiation |

| Packaging Details: | standard package for export |

| Delivery Time: | two months |

| Supply Ability: | 5 lines per year |

| Raw Materials: | Quartz Sand, Cement, Paper Fiber, Glass Fiber, Pulp, Additives, Etc | Fuel: | Coal, Gas, Heavy Oil, Light Oil, Diesel |

|---|---|---|---|

| Main Processes: | Pulping, Forming, Steaming, Drying, Sanding And Finishing Process | Characters Of Boards: | Light Weight, High Density, High Strength, Fiber Strength |

| Features Of Board: | Fireproof, Heat Insulation, Waterproof, Mould Proof, ,etc | Usage Of Board: | Ceiling Board ,fire Partition Panel, Air Flue, Fire Proof Door,etc |

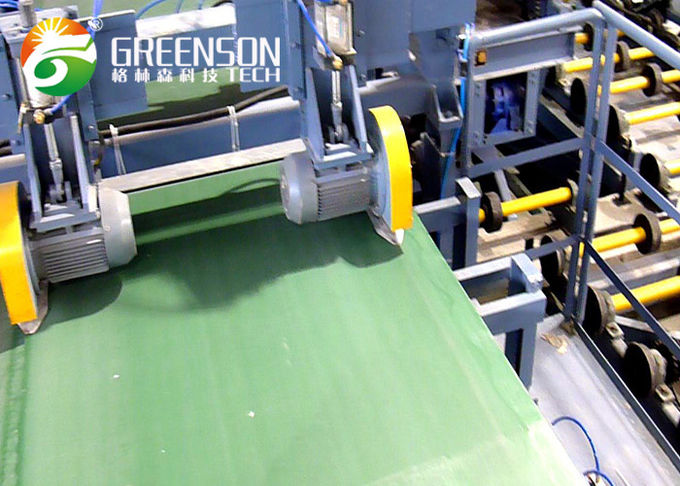

house designs Non-asbestos Fireproof Calcium Silicate Board Making Machine

Calcium silicate board is one new type of building material. It has lots of advantages such as

sound insulation, fireproof, waterproof, mouldproof, heat insulation, light, good strength etc.

This material is one kind of nontoxic,environment friendly,magnificent,multifuctional decorative

material,It completly meet current human's requirement.

The main raw materials are quartz sand, cement, hydrated calcium lime powder.

paper pulp, wollastonite and other accessories( mica, glass fiber, etc.)

The production process of calcium silicate board:

1.Quartz plasma processing

2.Paper processing

3.Pulping

4.Seperation, mixing and slurry control

5.Molding, answer the billet and stacking

6.Maintenance and stripping

7.Autoclaved maintenance

8.Drying

9.Sanding, edging and chamfering

Standard calcium silicate board dimension

Length: 2400-2440mm

Width: 1200-1220mm

Thickness: 4-30mm

It adopts slurry flowing method or hatschek method.We will provide one-stop service.

Contact Person: admin

Low Price Automatic Saw Machine For Gypsum Board Eco Friendly

Low Cost Plaster Board PVC and PET Full Automatic Laminating Line

Double Sides Full Automatic PVC Laminated Gypsum Ceiling Board Production Line

PLC System Gypsum Board Ceiling Making Punch Machine Saving Energy

Full Automatic Sheet Perforation Machine Gypsum Board Hydraulic Hole Punching Machine

Decorative Drywall Sheet Perforation Machine For Square / Round Hole

Heat Insulation Mineral Fiber Ceiling Board Machine Energy Saving

Automatic Operation Mineral Fiber Ceiling Board Machine With Waterproof / Fireproof

Light Weight Mineral Wool Board Production Line For Construction Material